Ventilation is the provision for circulation of fresh air within any habitable architectural structure. There are two kinds of ventilation: Mechanical and Natural Ventilation. Mechanical ventilation is when there are fans and exhausts to drive in or drive out fresh/stale air respectively, for air circulation. Second is, Natural Ventilation where there is an intentional passive air flow into the building which is planned for air circulation.

Then there is mixed ventilation mode which utilizes both Natural and Mixed ventilation systems for optimal air quality. Internorm’s unique I-tec Ventilation system is one step beyond: it has a heat exchanger integrated into the window system to avail more efficient air circulation than a natural ventilation does. This is a boon for homes in extreme weather conditions-cold or hot, when the weather does not permit opening or closing of the windows for a long time.

How does I-tec Ventilation ensure Energy Efficiency?

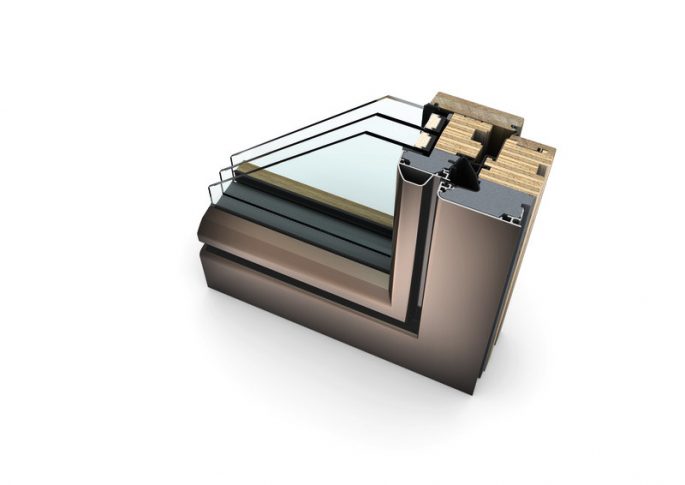

Internorm windows’ ventilation mechanism- fitted with a heat exchanger, is completely integrated into the window frame system. This supplies the interior with fresh air on a demand basis and makes it comfortable while simultaneously keeping the heat loss to a minimum.

Unregulated quick air exchange or permanent air leakage can lead to massive thermal and energy loss. Thus the heat exchanger is a safety net with an almost 93% heat recovery. It also reduces the energy losses to a minimum.

With I-Tec ventilation feature of the Internorm windows, rooms are ventilated automatically, thermally efficiently, and according to your personal specification.

How does this system contribute to your health?

Fresh air ensures clearer minds, better sleeping, increased concentration and generally improved performance. Allergy and hay fever sufferers can breathe clearly again by choosing the option of filters in the I-tech ventilation. This prevents fine dust and flower pollen from coming into your home. Due to the regulated I-Tec ventilation your home’s air quality will significantly improve.

Does integrating this system spoil the design?

No, only a narrow ventilation grid is visible on the outside and inside of the window. The windows look classy and modern without compromising the energy efficient,high-performance.

The ventilator is fitted during the installation of the windows and not after they are installed. This ensures the intactness of the design.

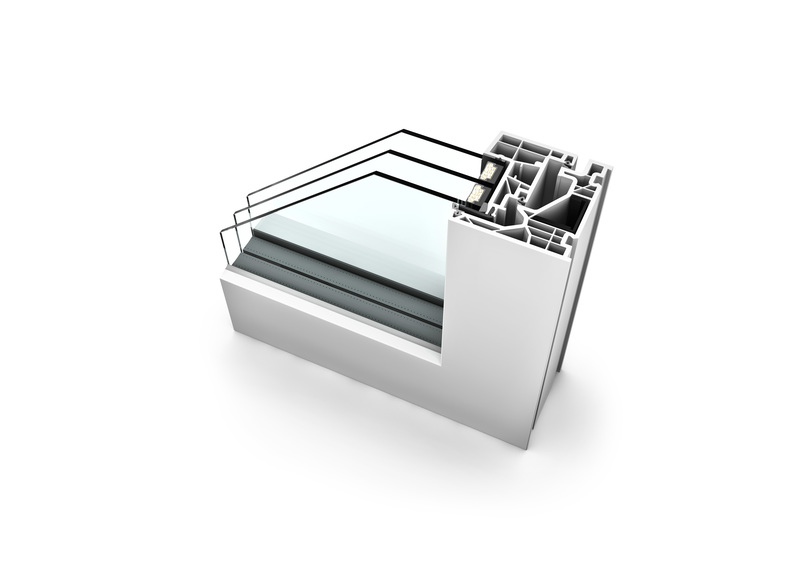

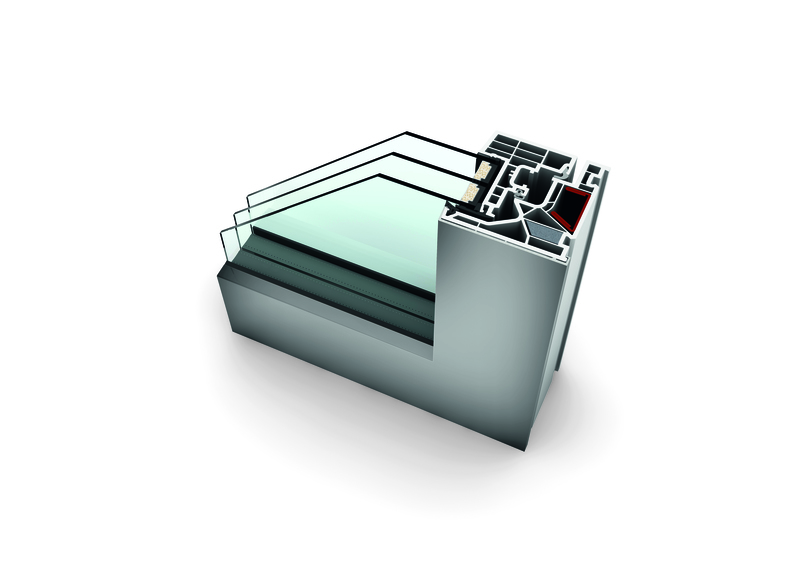

The I-Tec ventilator is fully concealed and integrated into the window systems KF 500, KF 410 et KV 440.

Does this system have any safety and security features?

Yes, the I-Tec ventilation system has tight security benefits. Due to the window staying closed during the air exchange and therefore, the locks remain engaged to ensure maximum protection against break in. When leaving the house there is no uncertainty as to whether the windows have been left open after airing, therefore giving ultimate peace of mind that your home is properly secure.

What are the other comfort factors that come along with I-tec Vent?

Windows that boast integrated I-Tec ventilation give your home a constant supply of clean, fresh air. Alternatively, damp, used air, unpleasant smells and pollutants are sucked out of your home and exchanged for fresh air. The control component is fitted to the window to enabling easy usage and convenient operation when ventilating your home. I-Tec ventilation can be controlled via the Smart Window App on your tablet or smart phone for incredibly easy usage.

The optional installation of filters prevents any fine dust or flower pollen from penetrating. The fan can be easily operated via a discreet control element attached directly to the window.

Can you covert these windows into smart windows?

Of course, yes! Internorm is a smart window product line!

If you want your home to be a more comfortable place , then Internorm’s I-tec SmartWindow could be a perfect solution. With this intelligent building control technology you can conveniently operate your windows’s ventilation and shading via your smartphone, tablet or PC – whether you’re at home or away.

Convenience is at the heart of Internorm’s I-tec SmartWindow. The easy-to-install system can be hooked up via your router to give you instant control of a range of features – from I-tec ventilation (giving you fresh air with minimal heat loss) and integral blinds through to fan light opening. You can roll shades up or down at the swipe of a screen and adjust the internal temperature to suit your requirements. The setup can be fitted with weather, temperature and humidity sensors to provide intelligent ventilation, too.

Furthermore, the technology can be extended to other home automation elements, such as dimmer lighting – you can fully adjust the living environment according to how you want to use a given room. Every element is controllable individually, but you can also pre-program various modes to suit activities such as watching movies, party set up, etc. You can even set up holiday modes so the house looks lived in while you’re away.

Whether you’re considering on renovation or new home building project, Internorm’s I-tec ventilation is the way to go! This integrated SmartWindow technology provides you the ability to make quick, convenient adjustments to the climate and atmosphere in your living spaces and hence, is a great choice!

INTERNORM PAR NEÜFENSTER SONT LES DISTRIBUTEURS EXCLUSIFS DE INTERNORM À TRAVERS LE CANADA. CONTACTEZ-NOUS NOW POUR PROGRAMMER UNE VISITE DE SALLES DE MONTRE AVEC LE PERSONNEL CONNAISSANT DE NEUFENSTER OU DEMANDEZ UNE ESTIMATION POUR VOS EXIGENCES DE FENÊTRES / PORTES PERSONNALISÉES.